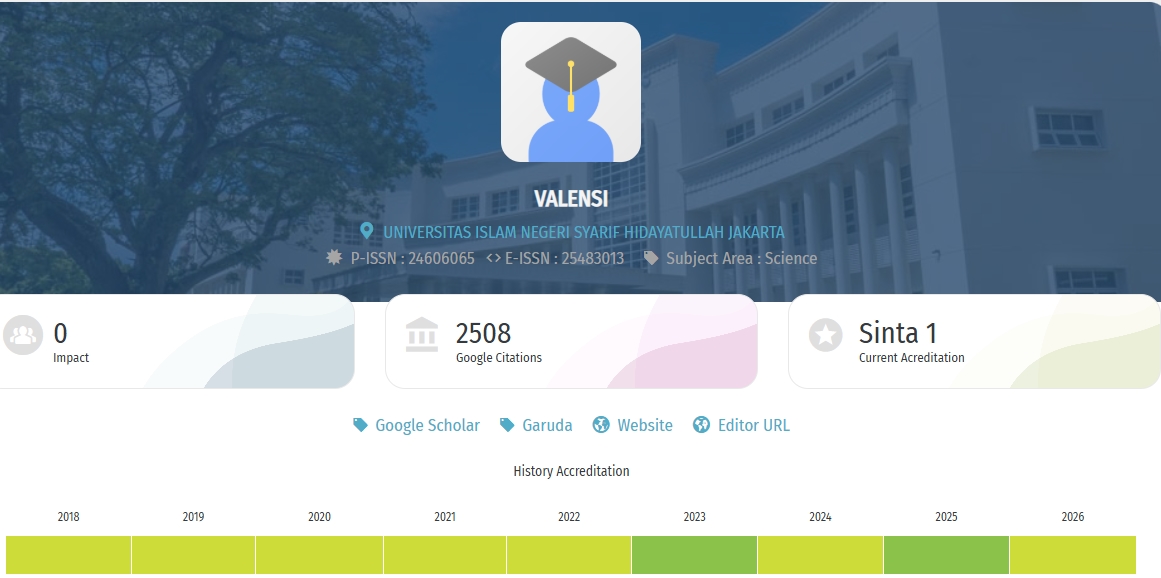

Hydrothermal Growth of Titanium Dioxide Thin Films on Conductive Substrates: Insights into Optical Properties

DOI:

https://doi.org/10.15408/jkv.v11i2.46532Keywords:

Hydrothermal, rutile, thin film, TiO2Abstract

Titanium dioxide (TiO2) thin films were deposited on fluorine-doped tin oxide (F:SnO2/FTO) conducting glass using the hydrothermal method. The X-ray diffraction (XRD) patterns confirmed that the TiO2 thin films crystallize in the rutile phase, exhibiting high crystallinity. The Fourier Transform Infrared (FTIR) spectrum confirmed the interaction between the FTO substrate and the TiO2 layer, indicated by an absorption peak in the range of 400 cm-1 to 900 cm-1. These peaks correspond to Ti–O–Ti and Ti–O vibrations within the octahedral structure of TiO₆ and Sn–O–Ti vibrations, indicating the bonding between the FTO substrate and the TiO₂ surface. Scanning Electron Microscopy (SEM) images provide detailed visualization of the morphological features of the TiO₂ thin films deposited on FTO glass, as evidenced by the prolonged hydrothermal processing resulting in the formation of thicker films. In addition, the interface between the TiO₂ layer and the FTO substrate is well-defined and continuous. UV-Visible Diffuse Reflectance Spectroscopy (UV-Vis DRS) analysis showed enhanced light absorption with increasing film thickness, which was also visually noticeable. As a result, the band gap energy decreases with increasing thickness, indicating that less energy is required to excite electrons from the valence band to the conduction band.

Downloads

References

1. Baig N, Kammakakam I, Falath W, Kammakakam I. Nanomaterials: A review of synthesis methods, properties, recent progress, and challenges. Mater Adv. 2021;2(6):1821-1871. doi:10.1039/d0ma00807a

2. Catania F, De Souza Oliveira H, Lugoda P, Cantarella G, Münzenrieder N. Thin-film electronics on active substrates: Review of materials, technologies and applications. J Phys D Appl Phys. 2022;55(32). doi:10.1088/1361-6463/ac6af4

3. Samanta C, Yuvaraja S, Zhama T, Zhao H, Gundlach L, Zeng Y. High-performance TiO2 thin film transistors: In-depth investigation of the correlation between interface traps and oxygen vacancies. [supplementary information].

4. Alotaibi AM, Promdet P, Hwang GB, Li J, Nair SP, Sathasivam S, Kafizas A, Carmalt CJ, Parkin IP. Zn and N codoped TiO2 thin films: Photocatalytic and bactericidal activity. ACS Appl Mater Interfaces. 2021;13(8):10480-10489. doi:10.1021/acsami.1c00304

5. Shabrina N, Salsabila NK, Sudarsono S, Yudoyono G. Characterization of the structure, morphology, and optical properties of titanium dioxide thin film deposited by spray pyrolysis technique for self-cleaning glass. J Phys Conf Ser. 2024;2780(1):012020. doi:10.1088/1742-6596/2780/1/012020

6. Oukassi S, Baggetto L, Dubarry C, Le Van-Jodin L, Poncet S, Salot R. Transparent thin film solid-state lithium ion batteries. ACS Appl Mater Interfaces. 2019;11(1):683-690. doi:10.1021/acsami.8b16364

7. Sun Z, huang L, Zhang Y, Wu X, Zhang M, Liang J, Bao Y, Xia X, Gu H, Homewood K, Lorenco M, Gao Y. Homojunction TiO2 thin film-based room-temperature working H2 sensors with non-noble metal electrodes. Sens Actuators B Chem. 2024;398:134675. doi:10.1016/j.snb.2023.134675

8. Rajan ST, Arockiarajan A. Thin film metallic glasses for bioimplants and surgical tools: A review. J Alloys Compd. 2021;876:159939. doi:10.1016/j.jallcom.2021.159939

9. Haider AJ, Jameel ZN, Al-Hussaini IHM. Review on: Titanium dioxide applications. Energy Procedia. 2019;157:17-29. doi:10.1016/j.egypro.2018.11.159

10. Sadhu S, Jaiswal A, Adyanthaya S, Poddar P. Surface chemistry and growth mechanism of highly oriented, single crystalline TiO2 nanorods on transparent conducting oxide coated glass substrates. RSC Adv. 2013;3(6):1933-1940. doi:10.1039/C2RA21516K

11. Kite SV, Sathe DJ, Patil SS, Bhosale PN, Garadkar KM. Nanostructured TiO2 thin films by chemical bath deposition method for high photoelectrochemical performance. Mater Res Express. 2019;6(2). doi:10.1088/2053-1591/aaed81

12. Salleh F, Usop R, Saugi NS, Salih EY, Mohamad M, Ikeda H, Sabri MFM, Ahmad MK, Said SM. Influence of TiO2 layer’s nanostructure on its thermoelectric power factor. Appl Surf Sci. 2019;497:143736. doi:10.1016/j.apsusc.2019.143736

13. Khizir H, Abbas T. Hydrothermal growth and controllable synthesis of flower-shaped TiO2 nanorods on FTO coated glass. Journal of Sol-Gel Science and Technology. 2021;98(3) (2021):487-496. doi:10.1007/s10971-021-05531-z

14. Prathan A, Sanglao J, Wang T, Bhoomanee C, Ruankham P, Gardchareon A, Wongratanaphisan D. Controlled structure and growth mechanism behind hydrothermal growth of TiO2 nanorods. Sci Rep. 2020;10(1):1-12. doi:10.1038/s41598-020-64510-6

15. Shilpa G, Mohan Kumar P, Kishore Kumar D, Deepthi PR, Sukhdev A, Bhaskar P. A rutile phase-TiO2 film via a facile hydrothermal method for photocatalytic methylene blue dye decolourization. Mater Today Proc. 2022;5477-5482. doi:10.1016/j.matpr.2022.04.148

16. Gupta T, Samriti, Cho J, Prakash J. Hydrothermal synthesis of TiO2 nanorods: formation chemistry, growth mechanism, and tailoring of surface properties for photocatalytic activities. Mater Today Chem. 2021;20:100428. doi:10.1016/j.mtchem.2021.100428

17. Senthamarai R, Ramakrishnan VM, Palanisamy B, Kulandhaivel S. Synthesis of TiO2 nanostructures by green approach as photoanodes for dye-sensitized solar cells. Int J Energy Res. 2021;45(2):3089-3096. doi:10.1002/er.6002

18. Zhang B, Tian Y, Zhang JX, Cai W. Structural, optical, electrical properties and FTIR studies of fluorine doped SnO2 films deposited by spray pyrolysis. J Mater Sci. 2011;46(6):1884-1889. doi:10.1007/s10853-010-5021-3

19. Orozco-Gonzalez LR, Acosta-Najarro DR, Magaña-Zavala CR, Tavizon-Pozos JA, Cervantes-Cuevas H, Chavez-Esquivel G. Photocatalytic degradation of naproxen using single-doped TiO2/FTO and co-doped TiO2-VO2/FTO thin films synthesized by sonochemistry. Int J Chem React Eng. 2023;21(4):493-510. doi:10.1515/ijcre-2022-0109

20. Taherniya A, Raoufi D. Thickness dependence of structural, optical and morphological properties of sol-gel derived TiO2 thin film. Mater Res Express. 2018;6(1):016417. doi:10.1088/2053-1591/aae4d0

21. Manickam K, Muthusamy V, Manickam S, Senthil TS, Periyasamy G, Shanmugam S. Effect of annealing temperature on structural, morphological and optical properties of nanocrystalline TiO2 thin films synthesized by sol–gel dip coating method. Mater Today Proc. 2020;23:68-72. doi:10.1016/j.matpr.2019.06.651

22. Jabbar S, Asif H, Ahmad R, Sharif S, Khan IA, Shafique MA. Changes in structural and optical properties of TiO2 thin films irradiated by various doses of 300 keV carbon ions. J Mater Eng Perform. 2024;33(12):6014-6023. doi:10.1007/s11665-023-08368-5

23. Kang M, Kim SW, Park HY. Optical properties of TiO2 thin films with crystal structure. J Phys Chem Solids. 2018;123:266-270. doi:10.1016/j.jpcs.2018.08.009

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Yulia Eka Putri, Tio Putra Wendari, Retno Dyah Wulandari, Melvi Muharmi, Mai Efdi, Refinel Refinel

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.